BULLDOZER SEM816D FOR SALE BEST PRICE IN CHINA

Features of bulldozer SEM816D

Hydrostatic Drive System

Upgraded hydrostatic system not only leverages Caterpillar automatic, dual path, hydrostatic drive with electronic control technology of the third generation TTT, but also increases efficiency and reliability.

Adopt Rexroth German new generation one case drive pump to combine control valve, track motor, simplified hose line design, continue to increase the reliability.

Caterpillar high pressure hose provides reliability and durability. Caterpillar control technology provides accurate control and high transmission efficiency.

Integrated the hydrostatic oil tank and implement hydraulic oil tank to improve filtrated precision and cooling capability of hydraulic system, increasing reliability and reducing maintenance cost.

Maintenance costs are reduced by 60% when compared competitors with torque converter and transmission and rear axle.

Comfortable Operation

Counter rotation—Tracks counter rotate to provide best in class maneuverability.

Powered turn—Machine maintains full power through turns to increase productivity.

Cruise control — Operators can retain previous speed settings which makes operation easily.

Multi-function joystick allows for counter-rotation, powered turn and cruise control.

Pilot joystick control provides comfortable precise blade operation.

Counter rotation, power turn and infinitely variable speed save lots of time,increasing working efficiency.

Semi-Universal Blade

SU blade combines the excellent penetration of the S blade and the high production capacity of the U blade.

Designed for superior load retention and penetration in tightly packed materials.

L-shaped push arms bring the blade closer to the machine, providing excellent maneuverability, balance and blade penetration.

Blades feature a strong box section design, made from high tensile strength steel to stand up to the most severe applications.

Undercarriage

Undercarriage is provided by China industry expert ensures high reliability and resistance to wear.

Carrier rollers track rollers and idle rollers are all maintenance free.

Planetary final drive design delivers increased torque ratio for higher transmission effi ciency and lower maintenance cost.

Durable final drive bearings and multiple wet disc brakes provide reliability, reduce system heat and extend overall life.

Structures

Machine structures are analyzed using Finite Element Analysis (FEA) and On Machine Stress Analysis (OMSA) to identify and protect high stress areas.

Advanced structure welding technique, relieving welding stress.

Cat ® Product Link™

Cat® Product Link™ will support your business, and accurately convey information of the equipment to relevant personnel in a timely and effective manner for your better equipment management.

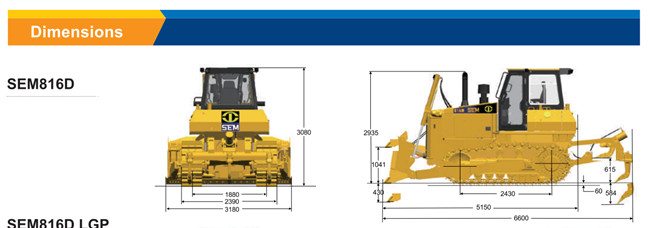

Specification of bulldozer SEM816D

| Model | SEM816D | SEM816D LGP | SEM816D DS | SEM816D CH | SEM816D FR |

| Main Specifications | |||||

|---|---|---|---|---|---|

| Operating Weight | 16,900kg | 19,490kg | 19,760kg | 17,160kg | 18,580kg |

| Ground Pressure | 66.8kPa | 31.1kPa | 34.8kPa | 61.8kPa | 66.9kPa |

| Ground Clearance | 410mm | 410mm | 410mm | 410mm | 410mm |

| Max. Slope | 30° | 30° | / | 30° | 30° |

| Engine | |||||

| Engine Model | WD10G178E25 | WD10G178E25 | WD10G178E25 | WD10G178E25 | WD10G178E25 |

| Rated Power | 131kW | 131kW | 131kW | 131kW | 131kW |

| Working Tool | |||||

| Blade Type | SU S | LGP | LGP | U | SU Forestry S Forestry |

| Blade Capacity | 4.3m³ 3.5m³ | 3.4m³ | 3.4m³ | 5.6m³ | 6m³ 5.8m³ |

| Blade Width | 3,180mm 3,590mm | 4,410mm | 4,410mm | 3,580mm | 3,180mm 3,590mm |

| Blade Height | 1,240mm 1,165mm | 1,000mm | 1,000mm | 1,400mm | 1,625mm 1,625mm |

| Max. Blade Digging Depth | 430mm 430mm | 470mm | 470mm | 430mm | 430mm 430mm |

| Max.Blade Lift Ground Clearance | 1,041mm 1,041mm | 1,055mm | 1,055mm | 1,041mm | 1,041mm 1,041mm |

| Max.Output Rimpull | 280kN 280kN | 280kN | 280kN | 280kN | 280kN |

| Max. Digging Depth of Ripper | 584mm | / | / | 584mm | 584mm |

| Max. Clearance Under Tip | 615mm | / | / | 615mm | 615mm |

| Powertrain | |||||

| Type | dual-path, closed loop electronically controlled hydrostatic drive system | dual-path, closed loop electronically controlled hydrostatic drive system | dual-path, closed loop electronically controlled hydrostatic drive system | dual-path, closed loop electronically controlled hydrostatic drive system | dual-path, closed loop electronically controlled hydrostatic drive system |

| Travel Speed-F/R | infinitely variable speeds 0-10 km/h | nfinitely variable speeds 0-10 km/h | infinitely variable speeds 0-10 km/h | infinitely variable speeds 0-10 km/h | infinitely variable speeds 0-10 km/h |

| Steering & Brake | hydrostatic steering; wet, multi-disc brake | hydrostatic steering; wet, multi-disc brake | hydrostatic steering; wet, multi-disc brake | hydrostatic steering; wet, multi-disc brake | hydrostatic steering; wet, multi-disc brake |

| Minimum Steering Radius | 3,610mm | 3,740mm | 3,740mm | 3,610mm | 3,610mm |

| Undercarriage | |||||

| Track Shoe Width-Single | 510mm | / | 950mm | 560mm | 560mm |

| Track Shoe Width-APEX | / | 1,050mm | 950mm | / | / |

| Track Shoe Quantity | 37 | 42 | 42 | 37 | 37 |

| Track Length on Ground | 2,430mm | 2,925mm | 2,925mm | 2,430mm | 2,430mm |

| Track Gauge | 1,880mm | 2,300mm | 2,300mm | 1,880mm | 1,880mm |

| Track Roller Quantity | 6 | 7 | 7 | 6 | 6 |

| Carrier Roller Quantity | 2 | 2 | 2 | 2 | 2 |

| Hydraulic System | |||||

| Type | center close, pilot control | center close, pilot control | center close, pilot control | center close, pilot control | center close, pilot control |

| Implement Hydraulic System Pressure | 19Mpa | 19Mpa | 19Mpa | 19Mpa | 19Mpa |

| Service Refil Capacities | |||||

| Fuel Tank | 320L | 320L | 320L | 320L | 320L |

| Cooling System | 45L | 45L | 45L | 45L | 45L |

| Hydraulic Tank | 140L | 140L | 140L | 140L | 140L |

| Pivot Shaft Case(each side) | 1.2L | 1.2L | 1.2L | 1.2L | 1.2L |

| Engine Crankcase | 24L | 24L | 24L | 24L | 24L |

| Final Drive(each side) | 30L | 40L | 40L | 30L | 30L |

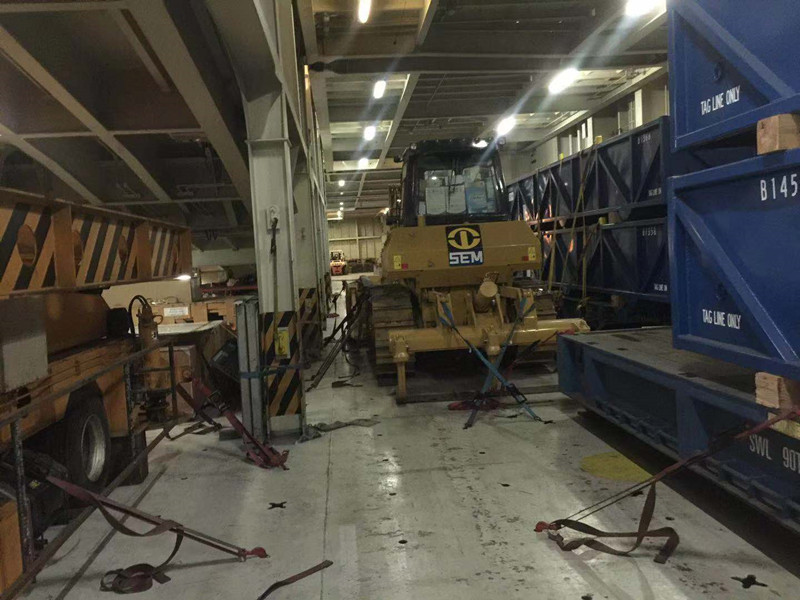

Bulldozer SEM816D RORO shipping,

BULLDOZER SEM816D bulk shipping,

Welcome to inquire anytime. Quotation with best price will be sent ASAP.